Physical Vapor Deposition Coatings; Highly Durable, Corrosion and Scratch Resistant

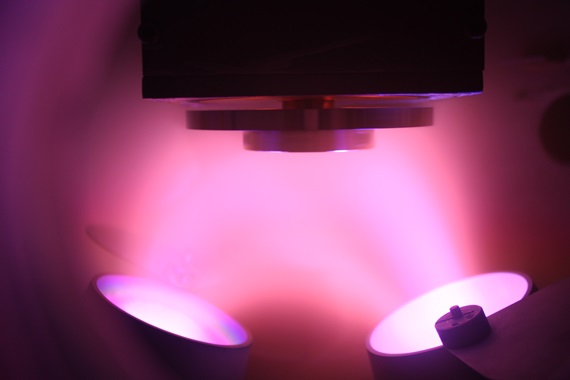

Physical vapor deposition refers to a variety

of deposition methods that can be used to produce thin coatings and films. Physical

vapor deposition is a process in which the surfaces of various products, such

as solar products, cutting tools, storage devices, microelectronics, medical

equipment, etc., are coated with materials to form a thin protective film. In

this process, the material transferred from condensed phase to vapor phase and

then back to the condensation phase of thin films. Physical vapor deposition coatings

are deposited for many reasons, such as to improve oxidation resistance, reduce

friction, and improve hardness and wear resistance.

Physical

vapor deposition is widely used in various applications, such as fabrication

of optical and conductive coatings, diffusion barriers, interconnects, and fuel

cell electrodes, surface modifications batteries, and microelectronic devices. Three

commonly used physical vapor deposition in almost all industries are ion

plating, sputtering, and thermal evaporation. It is extensively used in manufacturing

of aluminized PET film for food packaging, titanium nitride coated cutting

tools for metalworking, and semiconductor devices like thin-film solar panels.

Manufacturers/companies are extensively preferring

physical vapor deposition techniques over traditional techniques, due to the

eco-friendly properties, as well as other operational benefits, of the physical

vapor deposition process. Moreover, manufacturers are involved in different

business strategies to differentiate their products in an increasingly

competitive market. For instance, in 2019, Voestalpine Eifeler Coatings (based

in Germany) opened new physical vapor deposition facility in the United States to

provide physical vapor deposition coatings solutions to the manufacturing

communities.

The use of these types of techniques was

developed to aid in the coating and other techniques used in the industries

such as the aerospace, automotive, and other manufacturing industries. The

application of physical vapor deposition technique lies in the fact that it

provides a solid material that has been deposited on a substrate, which has a

temperature and a low level of vaporization. The physical vapor deposition of a

solid substrate is made possible by the use of a vacuum system that is coupled

with appropriate heating methods. Moreover, this technique allows the

depositing of solid material on the substrate without causing any damage to the

underlying substrate.

Comments

Post a Comment